Content Status

Type

Linked Node

Lead time

Learning ObjectivesLead time in SCM

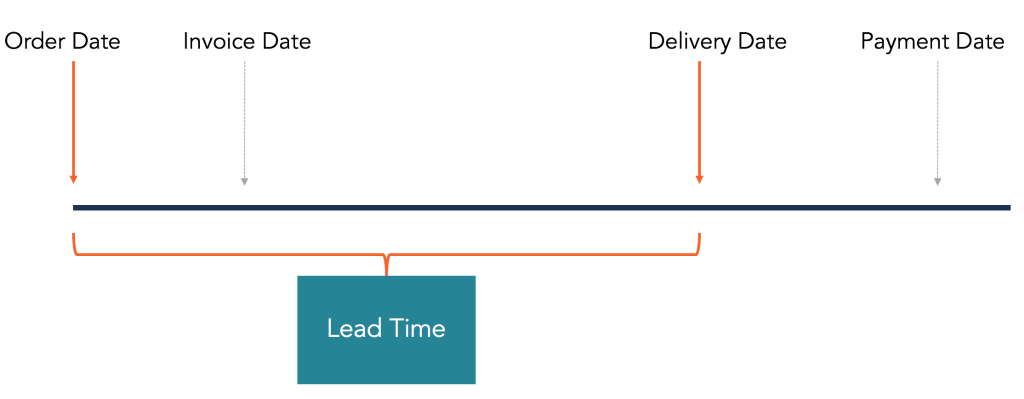

Lead time is defined as the time interval between the order generation for a product and its receipt/ availability for use. Lead time for a product depends upon the type of product, quantity available in the market/ manufacturer and the weather conditions in which it is transported.

In supply chain management lead time plays a very important role as it is mandatory to place reorders in time to avoid stocking out the product. Poorly managed lead time can lead to stock out and leads to delays in supplying the product to clients or end users.

Lead Time = Reordering delay (Time period) + Supply Delay (Time period)

Figure: Lead Time in Supply Chain Management

Benefits of Reduction in Lead Time

-

Minimises stock-outs

-

Helps to get medicines/ items on time

-

Reduces the wastage of inventory

-

Gives the estimation of demand

How to Reduce the Lead Time

-

Stop ordering surplus inventory

-

Keep an eye on the inventory level

-

Cut out as many steps as possible

-

Maintain the inventory as per the storage capacity

-

Continuous follow-up with the supplier or the facility

Resources

Assessment

| Question | Answer 1 | Answer 2 | Answer 3 | Answer 4 | Correct Answer | Correct explanation | Page ID | Part of Pre-Test | Part of Post-Test |

| Poorly managed lead time leads to stock-outs. | True | False | 1 | Poorly managed lead time can lead to stock out and leads to delays in supplying the product to clients or end-user. | Yes | Yes |

Content Creator

Reviewer

Target Audience

- Log in to post comments